The typical materials that we print with and that you can have something printed in are listed below.

PLA – ABS – Transparent – Nylon – Wood, Copper, and Bronze – Stainless Steel – Polyamide – Photopolymers

3D Printing with Nylon

We recommend that you come in for a personal consultation before having something printed in nylon. It is also recommended that you print your object in a different, cheaper material before printing it in nylon. Nylon prints stand out because of their incredible strength and stiffness. Thin shapes and tall prints have a tendency to delaminate so it only possible only to print certain kinds of shapes. The shape of a vase is definitely not a good object to print in nylon. This material is very porous and absorbent, and will accept color when dyed. Printing in nylon is very difficult and more risky, so there is a possibility it may be more expensive.

Below is a sample print that you can see has been colored.

Price of Nylon 3D Printing

The price of 3D printing with nylon depends on the time of printing the object. The price is around 300Kč per hour and the total price increases by 20% with each failed print. The customer will get the failed and the successful print. The optimal layer thickness for nylon is 0.2 mm. Below is a table that gives you a better idea of how layer thickness affects the print time.

Let us give you a quote for a model you would like printed. Send a 3D model in *.STL format to info@makerslab.cz and we will give you an estimate of the price.

You can also find us on 3D Hubs, where you can simply upload your 3D model in *.STL format to immediately receive a quote for your model.

Technology:

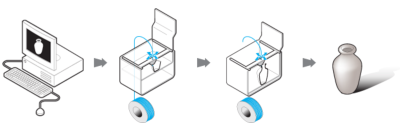

The principle of the 3D printing technology of Fused Deposition Modeling (FDM) is simple. It is similar to using a hot glue gun. The material is heated until medlted and then forced through a fine nozzle at the end of the glue gun. The difference is that the “flue” that is inserted into the printer is a long plastic wire called a filament. The nozzle of the printer moves and draws a pattern with the material layer by layer. When a model contains overhands, the printer builds support so that you can print in “thin air”. The supporting material must be removed when the print is finished.

Back to 3D Printing Service