The typical materials that we print with and that you can have something printed in are listed below.

PLA – ABS – Transparent – Nylon – Wood, Copper, and Bronze – Stainless Steel – Polyamide – Photopolymers

3D Printing Material ABS:

Models made with ABS are made of thermoplastic. ABS is suitable for both structurl and functional use. ABS models have a medium level of print detail. The quality of the surface of the model is rougher and occasionally spotty compared to other materials. The biggest advantage of using ABS is its chemical composition which allows for easy processing and can possibly be etched/glued using acetone. The disadvantage of using this material is that when printing larger sizes, the edges may curl slightly causing slight deformation near the print plate.

Price of 3D Printing ABS

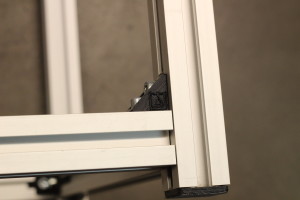

The price of 3D printing with ABS depends on both the time it takes to print and the size of the object. It typically comes out to be about 240 Kč per hour of printing. For example, the corner connector shown below is about 5 cm tall with layers of 300 microns prints in about half an hour. If printed with layers of 100 microns, it takes about two hours to print. In the table below, you can get idea of how layer size affects print time.

Examples of Prices:

Corner Connector : 120Kč (30 minutes)

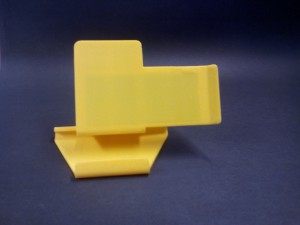

Tablet Stand : 1200Kč (5 hours )

Plug Stopper : 120Kč (30 minutes)

Let us give you a quote for a model you would like printed. Send a 3D model in *.STL format to info@makerslab.cz and we will give you an estimate of the price.

You can also find us on 3D Hubs, where you can simply upload your 3D model in *.STL format to immediately receive a quote for your model.

Technology:

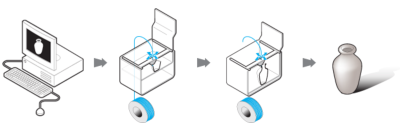

The principle of the 3D printing technology of Fused Deposition Modeling (FDM) is simple. It is similar to using a hot glue gun. The material is heated until medlted and then forced through a fine nozzle at the end of the glue gun. The difference is that the “flue” that is inserted into the printer is a long plastic wire called a filament. The nozzle of the printer moves and draws a pattern with the material layer by layer. When a model contains overhands, the printer builds support so that you can print in “thin air”. The supporting material must be removed when the print is finished.

Back to 3D Printing Service