The typical materials that we print with and that you can have something printed in are listed below.

PLA – ABS – Transparent – Nylon – Wood, Copper, and Bronze – Stainless Steel – Polyamide – Photopolymers

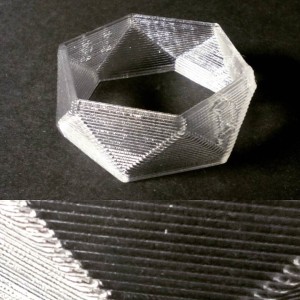

Transparent 3D Printing Material:

Both PLA and ABS can be transparent, but the most popular transparent materials are PET and PE.

If you are interested in having an object printed with transparent materials, there are a few factors to keep in mind:

- material is generally more expensive

- not completely transparent

- every shape and model will have different optical properties

- thicker layers = better appearance

- object will show all minor print errors

In general, transparent prints look more transparent when the object is printed with layers between 0.3 mm and 0.5 mm. It also turns out better if there is only one perimeter or edge (i.e. without fillers, holes, and large overhangs).

Price of Transparent 3D Printing

The price of 3D printing with transparent material depends of the time it takes to print and also on the size of the object. The prices range from 240Kč to 300kč per hour of printing. For example, the angel below has a layer height of 500 microns and prints in about 40 minutes. However, if printed with a layer height of 100 microns, it would take about two hours and would not look as nice. The layer height has a huge impact on the appearance of your object. In the table below, you can get an idea of how the layer size affects the print time.

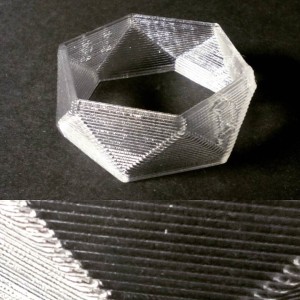

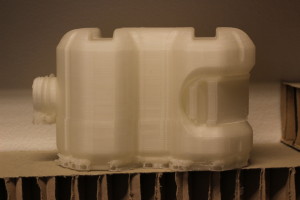

Examples of Prices:

Sample : 100Kč (20 minutes, material: PET)

Angel : 180Kč (40minutes , material: cristal clear)

Flask : 1200Kč (7 hours, material: PET)

Let us give you a quote for a model you would like printed. Send a 3D model in *.STL format to info@makerslab.cz and we will give you an estimate of the price.

You can also find us on 3D Hubs, where you can simply upload your 3D model in *.STL format to immediately receive a quote for your model.

Print Quote

Technology:

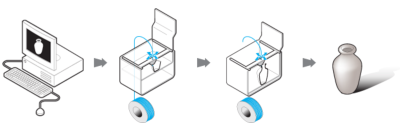

The principle of the 3D printing technology of Fused Deposition Modeling (FDM) is simple. It is similar to using a hot glue gun. The material is heated until medlted and then forced through a fine nozzle at the end of the glue gun. The difference is that the “flue” that is inserted into the printer is a long plastic wire called a filament. The nozzle of the printer moves and draws a pattern with the material layer by layer. When a model contains overhands, the printer builds support so that you can print in “thin air”. The supporting material must be removed when the print is finished.

Back to 3D Printing Service